Arming the Confederacy: Virginia's Mineral Contributions to the Confederate War Effort

by Robert C. Whisonant

Arming the Confederacy | Virginia’s mineral contribution to the Confederate war effort | Niter | Saltpeter | Potassium nitrate | Black powder | Colonel Isaac St. John | Niter and Mining Bureau | Wyeth County lead mines | Union Lead Mine Company | Saltville | Tredegar Iron Works | Midlothian Coalfields | Valley Coalfields.

The American Civil War is often seen as the first truly industrialized total war, one that consumed enormous amounts of human and material resources. But the two opponents were not evenly matched; the North had a preponderant share of raw materials, manufacturing ability, and population. On the eve of battle in April 1861, most of the mines, forges, and foundries in America were located in Union states. Some 90 per cent of the manufacturing capacity resided there— their factories made 97 percent of the firearms, 94 per cent of the cloth, 93 percent of the pig iron, and over 90 per cent of the boots and shoes. The disparity in the capability to make items necessary to the conduct of hostilities rested primarily on the North’s possession of more mineral riches, most particularly iron and coal, the foundation of heavy industry.

Within the Confederacy, Virginia had long been the foremost mineral producer. The greatest concentration of this natural wealth lay in the mountainous southwestern quarter of the state where large deposits of saltpeter, lead, salt, iron, and coal had been exploited for over a century. In addition, mines in the region yielded some copper, zinc, gold, and silver from time to time. To be sure, other parts of the South had mineral resources, notably Alabama with important iron and coal operations; none, however, rivaled the richness and variety of the troves in Southwest Virginia. This did not go unnoticed by Federal strategists intent on bringing down the Confederate war machine.

One of the natural resources most crucial to waging war in the Civil War era was an organic substance called saltpeter, known more commonly to the Confederates as niter. Potassium nitrate refined from niter provided the explosive power in the black gunpowder then used by the world’s armies and navies. Each powder grain had 75 per cent nitrate, 15 per cent charcoal, and 10 per cent sulfur. Niter had been mined in the United States since the earliest days of settlement, yet by 1860 most was imported, owing to decreased need in the long antebellum years of peace. The Confederacy continued to import saltpeter and gunpowder throughout the struggle, but the ever-tightening Union blockade of Southern ports soon proved the need for a stable home-grown niter and powder industry.

Once the opening shots thundered at Fort Sumter, the South acted quickly to ensure a steady supply of niter for the new powder mills being built. In April 1862, the Richmond government passed legislation to establish a Niter Corps within the Ordnance Department. A year later the government made the Niter Corps an independent agency and renamed it the Niter and Mining Bureau. This action enlarged the Bureau’s staff while handing it the responsibility for acquiring not just nitrates but also iron, copper, lead, coal, and zinc. An extremely able manager, Colonel Isaac Munroe St. John, headed the Bureau for the war’s duration. Despite increasing labor shortages and Federal capture of geographic areas harboring the saltpeter resources, St. John managed to expand niter production almost to the end of fighting.

The South had three domestic niter sources: cave sediments, the most plentiful; “dirt” under old buildings such as outhouses, barns, and stables; and nitriaries, or artificial niter beds. Caverns in the limestone belts of the Appalachian Mountains held immense volumes of high quality niter. This saltpeter is not primarily due to bat guano, as is commonly believed, but in fact occurs when underground waters dissolve nitrate in deciduous forest soils, then carry it into caverns where the nitrate precipitates in the cave sediments. The conditions of soil, water, and temperature necessary to generate the resource are best developed in the southeastern United States. Consequently, the mountain states of the old Confederacy had most of the niter caves in North America, from which excellent gunpowder, as good as any that could be imported, was derived.

To make that powder, impurities had to be removed from the raw niter. The first steps usually took place at the extraction site where workmen placed the saltpeter in tubs or barrels, then mixed it with water and potassium salts obtained by soaking wood ashes. Next came boiling in cast iron kettles until the crystals of potassium nitrate appeared. The ultimate destination of this crudely processed niter was the gunpowder mill where further refining by washing and boiling took place. Mill workers added sulfur and charcoal to the enriched nitrate, making the resultant compound highly explosive. Final processing dampened the mixture and pressed it into solid cakes. Vibrating wire screens separated the grains into different sizes – smaller ones for muskets and pistols and bigger ones for cannon.

Early in the war, nitriaries composed of a variety of human, animal, and vegetable waste were set up, usually near major cities. Workmen tended these “nitrate gardens” assiduously, wetting them down with urine from time to time, then turning the decomposing compost over to generate thin layers of saltpeter. The war years saw at least 13 nitriaries established, including some near Richmond; at Selma and Mobile, Alabama; at Charleston, South Carolina; and at Savannah and Macon, Georgia. Although a reliable source, the artificial beds needed months of cultivation before generating usable quantities of niter. Ultimately, most had not had enough time to yield significant nitrate crops before the close of combat in 1865.

Caves contributed the bulk of the Confederate domestic niter supply. Virginia, with an abundance of saltpeter caverns in the western highlands, led all other states by providing nearly 30 per cent of the total. The dispersed nature of the cave installations and their location in remote sections kept them relatively safe from Union raiders. With a dependable internal supply of niter and ongoing (albeit limited) importation, gunpowder shortages were generally not a problem for Rebel armies. In fact, when peace came, the Augusta Powder Works alone had 70,000 pounds on hand. The United States Artillery School used the leftover Augusta powder for gunnery practice at Fortress Monroe owing to its superb quality.

Lead was another strategic mineral product critical to Civil War armed forces. Without it, weapons would lack ammunition – no bullets for the rifles nor pellets for the shrapnel shells. In 1847, French Army Captain Claude-Etienne Minié had introduced an innovative lead bullet that transformed firearm technology. It was the first projectile to effectively grip the rifling or spiral grooves cut into a musket barrel. This spinning, aerodynamically shaped missile discharged from a rifled musket dramatically improved marksmanship and rate of fire over that of the old smoothbores. First used in substantial numbers by the British against Russian troops in the Crimean War (1853-1855), the Minié bullet led directly to the horrific totals of killed and maimed men on American Civil War battlefields.

Both Union and Confederate infantry fought almost exclusively with rifles shooting Minié bullets. Estimates are that 90 per cent of the casualties came from such weapons. Fighting men commonly referred to the “hailstorm of lead” tearing into them on battlefields; often they advanced leaning forward as if walking into a driving rain. Prodigious stores of lead were required to conduct such engagements, but the Confederacy had only one large-scale lead mining and smelting facility within its borders— the Wythe County operations deep in the mountains of southwestern Virginia. Just a handful of sporadically active workings were present elsewhere, and no significant domestic lead deposits besides Wythe County existed. It would be the Southwest Virginia mines together with importation that supplied the majority of Confederate lead.

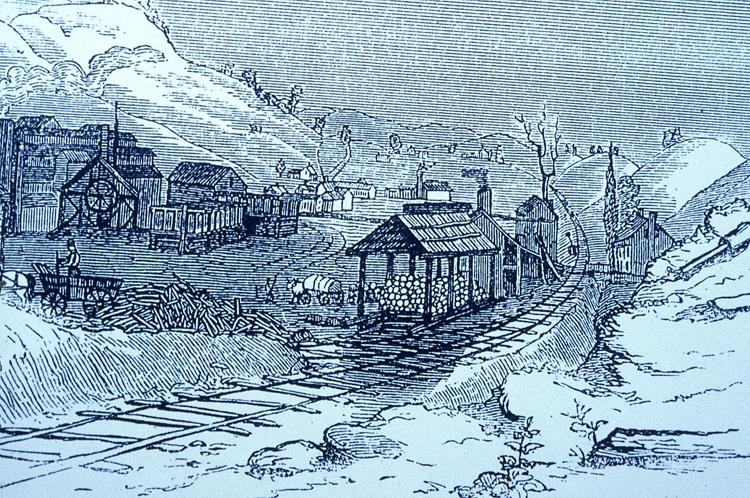

The Wythe County mines opened in the mid-1700s and served as the main source of lead balls for the muskets of the patriot armies during the Revolutionary War. The mines continued to operate into the first half of the 19th century, sending lead shot to markets throughout the Southern states. On March 8, 1860, with war clouds gathering, the Wythe County works were reorganized and incorporated as the Union Lead Mine Company, an ironic name for the foremost Confederate lead provider.

At the onset of fighting, the Richmond government demanded that the Union mines owners work the facilities to their maximum capacity or give them up for operation by the government. The company directors chose the former and round-the-clock activity commenced. The actual lead bullets were not made at the Wythe County site. Rather, the workmen dug out the ore, processed it in the smelters, cast the molten lead into ingots, and shipped the lead bars by rail to Richmond and Petersburg to be molded into ammunition. Production records are incomplete, but over three million pounds of lead, an estimated one-third of the total consumed by the Confederacy, are known to have come from the Union mines.

Still, even with this prolific output from Virginia, lead became increasingly scarce as the contest ground on. The government asked citizens for contributions of common household items containing lead, such as pipes, roofing materials, window weights, and eating utensils. In 1863, the city of Mobile ripped up unused lead water mains and shipped them off to the munitions plants. On occasion, officers directed soldiers back onto battlefields after the fighting ceased to scavenge for bullets to be recycled into fresh rounds.

The Northern high command eventually came to recognize the extreme importance of the Wythe County lead works and mounted a number of raids to destroy them. A July 1863 attack led by Union Colonel John T. Toland resulted in a pitched battle on the streets of Wytheville, about 10 miles away from the mines. Although the Federals won the engagement, Toland was killed and his soldiers withdrew back into West Virginia. Another expedition occurred in May 1864 in which Union cavalry under Brigadier General Woods William Averell clashed with Confederates led by Brigadier General John Hunt Morgan just north of Wytheville. Morgan drove Averell away and the lead works again escaped unscathed. In December 1864, a Northern force under Major General George Stoneman at last reached the mines and did much damage. The mines were running again by March 1865, but Stoneman’s men returned in April and laid waste to the facilities two days before Lee’s surrender at Appomattox.

After hostilities ceased, Confederate Ordnance officer Colonel William Broun summed up the contribution of the Wythe County mines: “Our lead was obtained chiefly, and in the last years of the war entirely, from the lead mines at Wytheville Virginia. The mines were worked night and day, and the lead converted into bullets as fast as received.” [1]

Of all Virginia’s mineral contributions, perhaps none held more importance to both the general population and the military forces of the Confederacy than salt. Early in the conflict, Union Major General William Tecumseh Sherman branded salt as a fundamental strategic resource: “Salt is eminently contraband, because of its use in curing meats, without which armies cannot be subsisted.” Besides preserving meat and other perishables, salt is essential in the human diet and in the Civil War, every soldier’s ration included it. Livestock required salt as well; a lack of it apparently fostered an outbreak of hoof and mouth disease among the cavalry horses of Lee’s army in 1862. Treating animal hides to make leather involved salt. Armies of that day used tremendous amounts of leather for soldiers’ shoes and accessories, and for horses’ bridles and saddles. Salt had a host of other applications in manufacturing pharmaceuticals and other chemical compounds. [2]

In Civil War times, salt production typically involved one of three methods: evaporation from saline springs or wells (the most common), boiling down sea water or water from salt lakes, and mining ancient layers of rock salt. At the outbreak of fighting, the Southern states had five noteworthy salt operations, these being on the Kanawha River near Charleston, Virginia (after June 1863, West Virginia); along Goose Creek in southeastern Kentucky; in Clarke County in southwestern Alabama; at Avery Island in southern Louisiana; and, most prolific of all, in southwestern Virginia at Saltville. The South lost the Goose Creek works almost immediately after the war commenced, as well as those on the Kanawha. The fall of Vicksburg on July 4, 1863, denied all of the extensive Louisiana sources to the eastern Confederacy. Thus, by mid-summer 1863, even though the Alabama brines still produced salt in the Gulf Coast area, Saltville was by far the major supplier to the states east of the Mississippi.

Native Americans took salt from the Saltville Valley’s abundant briny springs and ponds for thousands of years before white settlers began commercial endeavors in the late 1700s. In subsequent decades, entrepreneurs dug numerous wells to bring more brines to the surface where they were heated in iron kettles atop brick furnaces to precipitate the salt. By 1860, Saltville had grown to be one of the three largest salt-making centers in the United States. (The Kanawha works in northwestern Virginia and the massive installations at the Onondaga springs near Syracuse, New York, were the other two.)

In late summer of 1861, Stuart, Buchanan, and Company, the prime Saltville enterprise, negotiated a contract with the national government to provide salt “to and for the uses of the Confederate State armies.” Within the next year, Georgia, North Carolina, Tennessee, Alabama, Mississippi, South Carolina, Florida, and Virginia all worked out separate agreements with local businesses to procure the mineral or erected their own operations. At the peak of wartime production, the physical plant at Saltville included as many as 300 buildings containing 38 furnaces and 2,600 kettles. Salt output reached a maximum of four million bushels (200 million pounds) in 1864. [3]

Union sorties into the region to demolish the salt works began early, yet none reached Saltville before the fall of 1864. That changed on October 2, when a Federal unit from Kentucky that included a regiment of black soldiers, the 5th United States Colored Cavalry (5th USCC), stormed the defenses at Saltville only to be turned back. The Northerners withdrew in haste, leaving many of their wounded on the battlefield. The next day, Confederates sought out and shot the helpless still-living men of the 5th USCC left behind in what became known as the Saltville Massacre; a few whites were executed as well. The number of blacks murdered is in dispute, but something between 50 and 150 is commonly cited. Another Union command returned on December 20, broke through the defenders, and devastated much, though not all, of the salt works. A few weeks later, Saltville was up and running again, this time making salt until peace returned.

Although salt shortages happened from time to time during the struggle, thanks to Saltville more than any other source, the scarcity was never severe enough to cause serious problems for the military. Confederate Commissary General Lucius Bellinger Northrop noted in January 1865 that “…the supply of salt has always been sufficient and the Virginia works were able to meet demand for the army.” At the war’s conclusion, Saltville had provided approximately two-thirds of the Confederate salt. [4]

Iron, a mainstay of warfare for thousands of years, became even more indispensable in the Civil War. Railroads, ordnance, armor plate for the new ironclad warships, and a host of tools and machines vital to both civilians and the military required huge quantities of iron and steel. When war came, the Richmond-Petersburg complex of iron and steel mills, highly dependent on the state’s iron and coal resources, constituted nearly all of the Southern heavy industry. The crown jewel was the gigantic Tredegar Iron Works in the capital city, the only operation in the South that could make the big guns and iron plate needed immediately. It was a Tredegar mortar that lofted the signal shot opening the bombardment of Fort Sumter. Of the 48 pieces that shelled the fort, this company made at least 20. By the end of hostilities, Tredegar had manufactured almost half of the Confederate cannon and 90 per cent of the artillery ammunition.

Although not as well developed as Virginia’s, some iron industry did exist in other Confederate states as the war got underway. Alabama in particular possessed considerable reserves of ore, and furnaces and forges had sprung up at Selma and elsewhere across the state in the antebellum years. In the course of the conflict, the Alabama iron operations expanded swiftly and managed to overtake the Virginia producers. In the end, the two states generated about 90 per cent of the Confederate iron. Smaller iron works were located in five other Southern states – North and South Carolina, Georgia, Tennessee, and Mississippi.

Though the domestic iron output increased during the war, the Confederacy never had enough. The amounts necessary just for the railroads completely overwhelmed the production system. To maintain and extend the lines would use an estimated 50,000 tons of rolled steel a year, yet the combined capacity of all the Southern furnaces totaled only about 20,000 tons a year. Moreover, the Confederate tracks and rolling stock began the war much inferior to the North’s, and soon the persistent lack of iron made simply keeping the trains running the most pressing problem. As early as 1862, work crews routinely ripped out rails from smaller lines to replace those in the more valuable arteries. The last rail ever made in the Confederacy had been manufactured the year before.

Iron making began with the smelting of ore in charcoal-fired furnaces to produce the refined bars or “pigs” for shipment to the larger forges and foundries such as the Tredegar Works. The exact numbers and locations of the Southern furnaces are not known, but a detailed Niter and Mining Bureau report in January 1865 noted that the national government operated seven furnaces in 1864 – three in Virginia and two each in Alabama and Texas. Forty-five more privately-owned furnaces were in blast at one time or another that year, 20 of them in Virginia and nine in Alabama. About 80 per cent of the Virginia furnaces lay in the western mountains where they remained relatively safe from harm until late in the contest.

No Union campaign ever targeted the western Virginia iron furnaces as the single operational goal. Like the niter caves, the furnace sites were too numerous and too scattered to be the primary focus of an enemy offensive. Regardless, Federal raiders often found them when they penetrated deeper into the remote highlands as the war went on. In summer 1864, Union Major General David Hunter led a force into the southern Shenandoah Valley, hoping to take Staunton and then attack Lynchburg, an important industrial and rail center. Though driven away from Lynchburg, the Northern soldiers discovered three of the biggest and best Tredegar-owned furnaces during the foray which they reduced to smoldering ruins. In December 1864, General George Stoneman invaded Southwest Virginia to assault Saltville, the lead mines near Wytheville, and the Virginia and Tennessee Railroad. His troopers came upon and pillaged several iron operations.

By the 1860s, coal was rapidly replacing wood to power the new iron machines essential to conflict, especially railroad locomotives and armored warships, and to fuel the factories that made such devices. Nowhere is the growing importance of coal better exemplified than by the March 9, 1862, clash between the USS Monitor and the CSS Virginia on the waters of Hampton Roads, Virginia. That benchmark day witnessed two historic firsts in naval engagements: both warships were covered with iron plate and both were propelled by coal-fired steam engines. Coal and iron were now inextricably linked as keys to the successful prosecution of warfare.

In mid-19th century America, one Northern state— Pennsylvania— possessed three-fourths of the world’s known deposits of anthracite. This hot-burning, carbon-rich coal was extremely desirable for the high-temperature furnaces making pig iron. The anthracite-fired metal was much less expensive to make than that from the less efficient charcoal-burning furnaces more commonly used in the South. The abundance of anthracite had prompted a fundamental relocation of American iron manufacturing to Pennsylvania in the antebellum years. There the numbers of furnaces and forges grew rapidly and gave rise to a supporting network of railroads, all of which had the North’s heavy industry well on the way to world-class status when open warfare finally erupted in 1861.

In contrast, the states that comprised the Confederacy, with the notable exception of Virginia, had failed to build up a strong coal mining industry to undergird iron making. Besides Virginia, sizeable accumulations of bituminous coal had been found in Kentucky, Tennessee, and Alabama. The Midlothian coalfields, however, just west of Richmond were much more developed than any others in the South. Discovered around 1700, Midlothian coal became the first in America to undergo commercial-scale production in 1748. A century later, these mines were providing energy for the forges and foundries in the capital city and had even given rise to a small railroad network, similar to the much larger Pennsylvania system. During the war, the Midlothian fields produced over 100,000 tons of coal annually. Much of that output went directly to the Tredegar Iron Works, the heart of the Confederate industrial war effort.

Across the state from the Richmond fields, Southwest Virginia coal had been mined in Montgomery County near Blacksburg since the late 1700s. Known generally as the Valley coal fields, these beds are semi-anthracites, significantly higher in grade than the bituminous Midlothian coal. During the war, the Confederate government obtained coal from one of the Montgomery County mines and shipped it eastward to Richmond and Norfolk. The tradition has grown up that this coal was placed in the bunkers of the South’s first armored warship and stoked her engines in the epic battle with the Monitor.

In summary, Virginia turned out massive amounts niter, lead, salt, iron, and coal for the Confederacy. The state also contributed copper and zinc, though in much smaller quantities. Some historians have contended that one of the main reasons for shifting the Confederate capital from Montgomery, Alabama, to Richmond in 1861 was to ensure that Virginia’s industrial might and vast natural resources would be staunchly defended to the very end, as indeed they were. Lee, Jackson, and the Army of Northern Virginia would go on to great glory and legendary status, but from the beginning, perceptive Confederate leaders knew that Virginia’s mineral wealth and manufacturing based on those resources would be requisite to arming and sustaining the South in a prolonged, resources-intensive conflagration.

- [1] James I. Robertson, Jr., “Lead” in R. N. Current et al, ed., 4 vols. Encyclopedia of the Confederacy (New York: Simon and Schuster, 1993), 913.

- [2] M. Kurlansky, Salt: A World History, Penguin ed. (New York: Walker, 2002), 260.

- [3] Saltville Historical Foundation, Saltville and the Civil War (Saltville, VA: Saltville Historical Foundation), undated informational brochure.

- [4] M.E. Holmes, “Salt” in R. N. Current, Encyclopedia, 1362.

If you can read only one book:

Whisonant, Robert C. Arming the Confederacy: How Virginia’s Minerals Forged the Rebel War Machine. New York: Springer Publishing Company, 2015.

Books:

Austin, V. L. The Southwest Virginia Lead Works, 1756-1802. Blacksburg, VA: Master’s Thesis, Virginia Polytechnic Institute and State University, 1977.

Bruce, Kathleen. Virginia Iron Manufacture in the Slave Era. New York: The Century Company, 1930.

Hibbard, Walter R. Virginia Coal: An Abridged History. Blacksburg, VA: Virginia Center for Coal and Energy Research, 1990.

Kegley, Mary B. Wythe County Virginia: A Bicentennial History. Wytheville, VA: Wythe County Board of Supervisors, 1989.

Lonn, Ella. Salt as a Factor in the Confederacy. New York: Walter Neale, 1933.

Lynch, Michael E. Confederate War Industry: The Niter and Mining Bureau. Richmond, VA: Master’s Thesis, Virginia Commonwealth University, 2001.

Mandigo, Howard M. Manufacturing Iron along the New River in Virginia, in Mary B. Kegley, Glimpses of Wythe County, Orange, VA: Central Virginia Newspapers, 1986, 115-24.

Proco, Garland. Merrimac Mines: A Personal History. Blacksburg, VA: Southern Printing, 1994.

Vandiver, Frank E. Ploughshares into Swords: Josiah Gorgas and Confederate Ordnance. Austin: University of Texas Press, 1952.

Watson, Thomas L. Mineral Resources of Virginia. Lynchburg, VA: J. P. Bell Company, 1907.

Organizations:

No organizations listed.

Web Resources:

No web resources listed.

Other Sources:

No other sources listed.